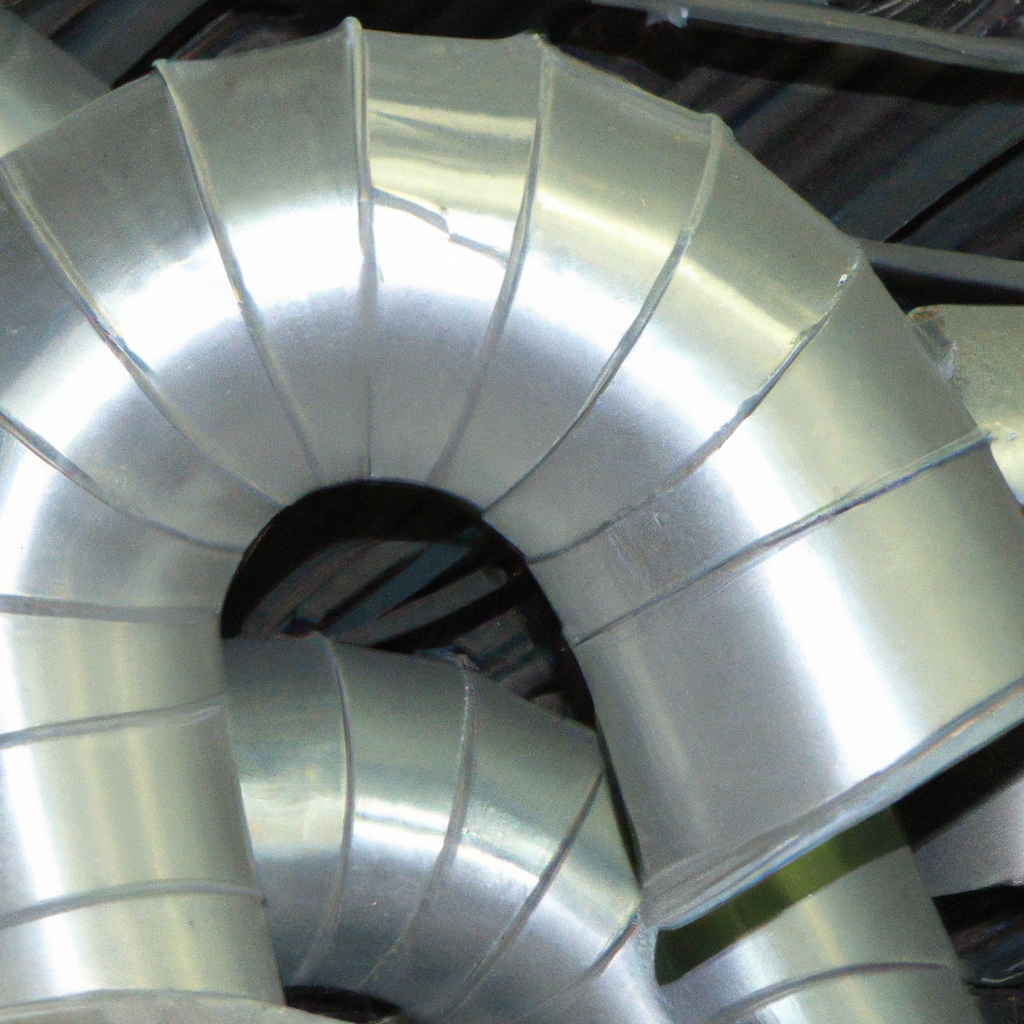

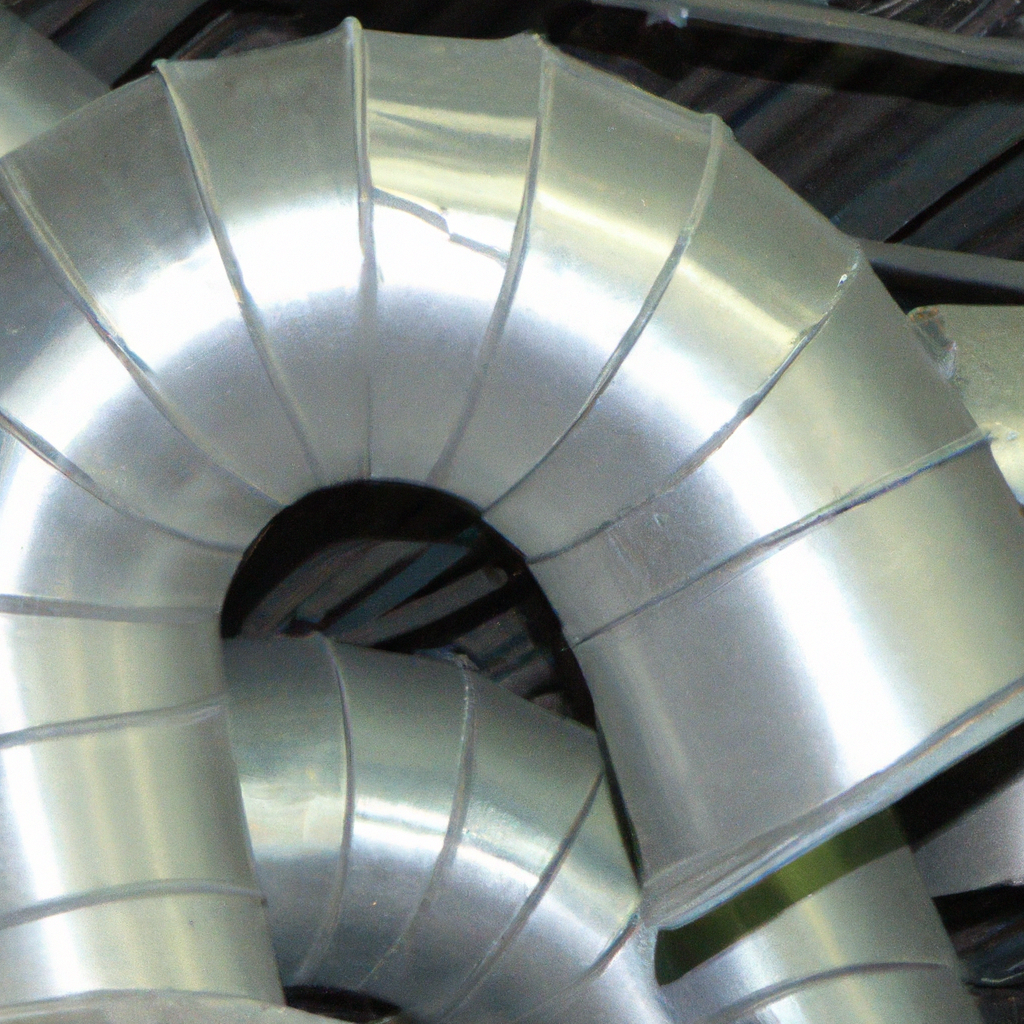

In the world of HVAC systems, ductwork plays a crucial role in delivering and distributing air efficiently throughout a building. When it comes to choosing the right ductwork, it’s important to understand that there are different types available, each with its own unique features and benefits. Rectangular, round, and spiral are the three main types of ductwork that you may come across. Rectangular ducts are known for their versatility and ease of installation, round ducts offer smoother airflow and better energy efficiency, while spiral ducts provide a sleek and aesthetically pleasing option. Depending on your specific needs and preferences, selecting the right type of ductwork can have a significant impact on the overall performance of your HVAC system.

Rectangular Ductwork

Definition and Characteristics

Rectangular ductwork refers to a type of air distribution system that is constructed in a rectangular shape. It is made from sheet metal and is commonly used in HVAC (Heating, Ventilation, and Air Conditioning) systems to transport air from one location to another. The ductwork is designed to create a smooth and efficient airflow, ensuring that the conditioned air reaches its intended destination effectively.

One of the main characteristics of rectangular ductwork is its shape. Unlike round or spiral ductwork, which have a circular cross-section, rectangular ductwork has a rectangular shape, with four sides and four corners. This shape allows for easy installation and connection to various HVAC components, such as air handlers, fans, and air vents.

Rectangular ductwork is also known for its durability and strength. It is typically made from galvanized steel or aluminum, both of which are strong materials that can withstand high air pressures and temperature differentials. This makes rectangular ductwork suitable for different types of HVAC applications, including residential, commercial, and industrial settings.

Advantages

Rectangular ductwork offers several advantages that make it a popular choice for HVAC systems:

-

Space Efficiency: The rectangular shape of the ductwork allows for efficient use of available space. It can be easily installed in tight or confined areas, such as attics, crawl spaces, and wall cavities. The rectangular design also allows for easy integration with other building components, such as insulation and drywall.

-

Airflow Control: Rectangular ductwork provides excellent control over airflow. The straight sides of the ducts minimize air turbulence, resulting in a more efficient and consistent airflow throughout the system. This ensures that conditioned air is evenly distributed, reducing temperature variations and improving overall comfort.

-

Lower Air Leakage: Rectangular ductwork is known for its low air leakage rate compared to other types of ductwork. The rectangular shape and sealed joints minimize air loss, preventing wasted energy and reducing the workload on HVAC systems. This can lead to lower energy consumption and cost savings over time.

-

Easy Maintenance: Rectangular ductwork is relatively easy to access and maintain. With its flat surfaces and right angles, it is easier to clean and inspect compared to round or spiral ductwork. This simplifies routine maintenance tasks, such as removing dust and debris, inspecting for leaks, and replacing damaged sections.

Disadvantages

While rectangular ductwork offers numerous advantages, it also has a few limitations that should be considered:

-

Installation Complexity: Installing rectangular ductwork can be more complex and time-consuming compared to other types of ductwork. The rigid nature of the ducts requires precise measurements and careful planning to ensure proper fit and alignment. This may require professional installation services, adding to the overall cost.

-

Airflow Noise: The rectangular shape of the ductwork can sometimes cause air turbulence and increased noise levels. This can be mitigated through proper design and the use of noise-reducing materials, such as insulation and sound baffles. However, extra care should be taken to ensure a quiet and comfortable indoor environment, especially in noise-sensitive applications.

-

Higher Material Costs: Rectangular ductwork can be more expensive to manufacture and install compared to round or spiral ductwork. The use of sheet metal and the need for precise fabrication adds to the overall material and labor costs. However, the long-term energy savings and durability of rectangular ductwork can offset these initial costs.

Applications

Rectangular ductwork is widely used in various HVAC applications, including:

-

Residential HVAC: Rectangular ductwork is commonly found in residential buildings, such as houses and apartments. It is used to distribute conditioned air from the central air conditioner or furnace to different rooms and areas within the building. The space-efficient design of rectangular ductwork makes it ideal for residential settings with limited space.

-

Commercial HVAC: Rectangular ductwork is extensively used in commercial buildings, such as offices, retail stores, and hospitals. It provides efficient and controlled airflow, helping maintain comfortable indoor environments for occupants. The low air leakage rate and ease of maintenance make rectangular ductwork suitable for high-demand commercial applications.

-

Industrial HVAC: Rectangular ductwork is also utilized in industrial settings, including factories, warehouses, and manufacturing facilities. It is capable of handling large air volumes and higher air pressures required for industrial processes. The durability and strength of rectangular ductwork make it suitable for industrial environments with harsh operating conditions.

In conclusion, rectangular ductwork offers several advantages, such as space efficiency, airflow control, lower air leakage, and easy maintenance. However, it also has limitations, including installation complexity, potential airflow noise, and higher material costs. Understanding the characteristics and applications of rectangular ductwork can help in making informed decisions when designing or upgrading HVAC systems in different settings.