In order to meet building codes and prioritize safety, certain ductwork installations may necessitate the use of fire-resistant materials. These materials are specifically designed to withstand high temperatures and prevent the spread of fire throughout a building’s ventilation system. By incorporating fire-resistant materials, you can enhance the overall safety of a structure, reducing the risk of fire-related incidents and providing peace of mind for occupants.

This image is property of www.hfmmagazine.com.

Why fire-resistant materials are necessary for ductwork installations?

Building code requirements

Fire-resistant materials for ductwork installations are necessary to comply with building code requirements. Building codes set forth guidelines and regulations that aim to ensure the safety of occupants in buildings. These codes often mandate the use of fire-resistant materials in areas where there is a risk of fire, including ductwork installations. By adhering to these building code requirements, you can ensure that your ductwork is up to standard and protect against potential fire hazards.

Enhancing safety

The primary reason for using fire-resistant materials in ductwork installations is to enhance safety. Ductwork can act as a conduit for the spread of fire and smoke throughout a building. By utilizing fire-resistant materials, you can minimize the potential for fire to spread through the ducts, keeping occupants safe and allowing them more time to evacuate in the event of a fire.

Preventing fire spread

Fire-resistant materials play a crucial role in preventing the spread of fire through ductwork installations. These materials are designed to resist the intense heat generated by a fire, providing a barrier that helps contain the flames. By preventing fire from spreading through the ducts, fire-resistant materials can help limit property damage and facilitate the firefighting efforts of first responders.

Types of ductwork installations that require fire-resistant materials

Commercial buildings

Ductwork installations in commercial buildings often require fire-resistant materials due to the higher occupancy rates and potential fire risks associated with these spaces. Commercial buildings, such as office complexes, retail stores, and hospitals, often house large numbers of people and contain various sources of ignition. To protect the occupants and minimize property damage, fire-resistant materials are essential in commercial ductwork installations.

Residential buildings

Fire-resistant materials are also necessary for ductwork installations in residential buildings. While the risk of fire may be lower compared to commercial buildings, residential structures still require adequate protection. Residential homes, apartment buildings, and condominiums can benefit from the use of fire-resistant materials to prevent the spread of fire and smoke through the ductwork, providing valuable time for occupants to escape safely.

Industrial facilities

Industrial facilities, such as factories, warehouses, and power plants, pose unique fire hazards due to the presence of flammable materials and potentially hazardous processes. Ductwork installations in these facilities must meet stringent fire safety standards. Fire-resistant materials are crucial in industrial ductwork to prevent the rapid spread of fire and protect critical equipment and infrastructure.

Fire-resistant materials for ductwork installations

Fire-rated ducts

Fire-rated ductwork is specifically designed to withstand the heat of a fire and maintain structural integrity. These ducts are made from fire-resistant materials, such as steel or specially treated aluminum, and are capable of preventing the spread of flames and smoke. Fire-rated ducts are available in various configurations, including rectangular, round, and oval, to suit different installation requirements.

Fire dampers

Fire dampers are mechanical devices installed within a ductwork system to regulate the flow of air and prevent the spread of fire and smoke. These dampers automatically close when exposed to high temperatures, effectively sealing off a duct to limit the spread of flames. Fire dampers play a critical role in compartmentalizing a building and preventing the spread of fire between different areas.

Fire-resistant coatings

Fire-resistant coatings are applied to the surfaces of ductwork to provide an additional layer of protection against fire. These coatings are typically intumescent, meaning they expand when exposed to heat, forming a thick insulating layer that helps prevent the transmission of heat to the duct’s interior. Fire-resistant coatings can be applied to ductwork made from various materials, including galvanized steel and fiberglass.

Building codes and regulations for ductwork installations

International Building Code (IBC)

The International Building Code (IBC) is a widely adopted set of regulations and standards for the construction and maintenance of buildings. The IBC includes specific requirements for ductwork installations to ensure fire safety. These requirements outline the type of fire-resistant materials, installation methods, and testing and certification procedures necessary to meet code compliance.

National Fire Protection Association (NFPA) standards

The National Fire Protection Association (NFPA) is a leading organization dedicated to fire prevention and safety. The NFPA develops and publishes standards that address various aspects of fire protection, including ductwork installations. The NFPA standards, such as NFPA 90A for air-conditioning and ventilation systems, specify the design, construction, and maintenance requirements for ductwork to mitigate fire risks.

Local building codes

In addition to the IBC and NFPA standards, local building codes may also dictate specific regulations for ductwork installations. These codes are jurisdiction-specific and may include additional requirements or modifications to the national standards. It is crucial to consult local authorities or building officials to ensure compliance with the applicable building codes and regulations in your area.

This image is property of www.hfmmagazine.com.

Installation considerations for fire-resistant ductwork

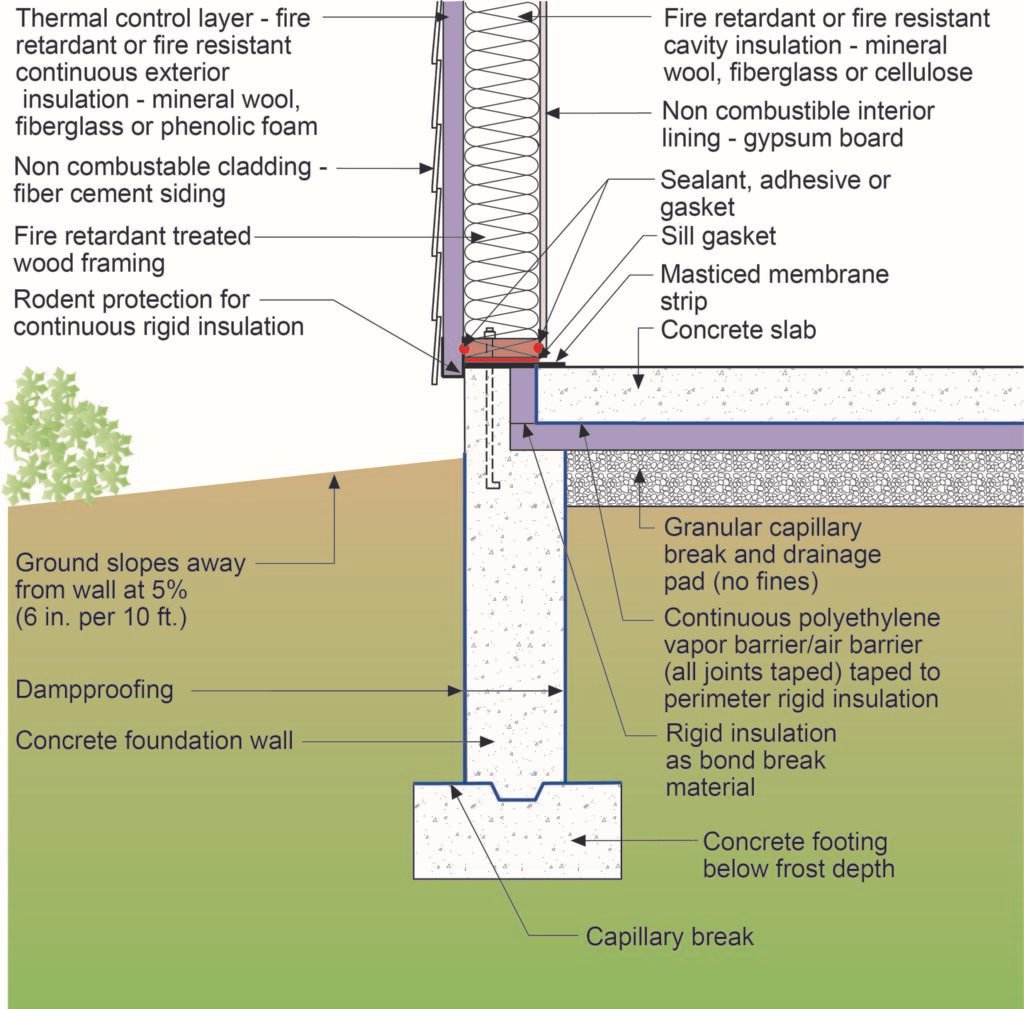

Proper sealing and insulation

Proper sealing and insulation of ductwork are crucial for its fire-resistant properties. Any gaps or leaks in the ductwork can compromise the effectiveness of fire-resistant materials. Sealing duct joints with fire-resistant materials, such as specialized tapes or sealants, can help ensure a tight seal. Additionally, insulating ductwork with fire-resistant insulation materials can further enhance its ability to withstand the heat of a fire.

Maintaining clearances

It is important to maintain proper clearances between fire-resistant ductwork and other building components. Clearances ensure that the ducts can expand and contract without coming into contact with other materials, reducing the risk of damage and maintaining the integrity of the fire-resistant materials. Following manufacturer recommendations and consulting building codes can help determine the required clearances for your specific ductwork installation.

Regular inspections and maintenance

Regular inspections and maintenance are essential to ensure the continued effectiveness of fire-resistant ductwork. Ductwork should be inspected for any signs of damage, such as cracks or corrosion, that may compromise its fire-resistant properties. Additionally, regular cleaning and filter replacement can help prevent the accumulation of debris, which can be a fire hazard. It is recommended to establish a maintenance schedule and perform inspections at least annually or as directed by applicable regulations.

Fire-resistant ductwork testing and certification

ASTM E2336 standard

The ASTM E2336 standard provides guidelines for the testing and certification of fire-resistant ductwork systems. This standard involves subjecting the ducts to a series of fire tests to evaluate their performance under various conditions. The tests assess criteria such as flame propagation, temperature rise, and structural integrity. Ductwork that meets the requirements of ASTM E2336 can be considered reliable in preventing the spread of fire and may carry a fire resistance rating.

UL 181 certification

UL 181 certification is a widely recognized certification for ductwork materials and products. This certification ensures that the tested materials meet the necessary fire safety criteria and can be used in specific applications. UL 181 certification covers various aspects of ductwork, including sealing materials, flexible air ducts, and factory-made rigid air ducts. Choosing UL 181 certified products can provide assurance of compliance with fire safety standards.

Fire rating classifications

Fire rating classifications are used to categorize the fire resistance of ductwork materials and products. These classifications are typically based on various factors, such as flame spread, smoke generation, and structural integrity. Common fire rating classifications include Class 0, Class 1, and Class 2, with higher classes indicating greater fire resistance. When selecting fire-resistant materials for ductwork installations, it is essential to consider the specific fire rating requirements outlined by building codes and regulations.

This image is property of www.wbdg.org.

Cost implications of using fire-resistant materials

Initial installation costs

The use of fire-resistant materials in ductwork installations may incur slightly higher initial installation costs compared to standard materials. Fire-rated ducts, fire dampers, and fire-resistant coatings may be more expensive than their non-fire-resistant counterparts. However, the price difference is relatively small compared to the potential costs of property damage and loss of life in the event of a fire. Investing in fire-resistant materials during the initial installation can help provide long-term safety benefits and peace of mind.

Long-term savings

While fire-resistant materials may have higher upfront costs, they can result in long-term savings. By effectively preventing the spread of fire through ductwork, these materials can help minimize property damage, reduce repair and replacement costs, and potentially decrease insurance premiums. Furthermore, fire-resistant materials often have longer lifespans and require less frequent maintenance, leading to additional cost savings over time.

Insurance benefits

Utilizing fire-resistant materials in ductwork installations can have insurance-related benefits. Insurance companies often offer discounts or incentives for buildings that meet specific fire safety standards, including the use of fire-resistant materials. By complying with building codes and regulations and incorporating fire-resistant materials, you may qualify for lower insurance premiums, reducing the overall cost of protecting your property.

Common challenges with fire-resistant ductwork installations

Integration with HVAC systems

One common challenge with fire-resistant ductwork installations is ensuring seamless integration with heating, ventilation, and air conditioning (HVAC) systems. HVAC systems rely on the proper distribution of air through ductwork, and the incorporation of fire-resistant materials should not hinder the system’s functionality. Careful planning and coordination with HVAC contractors or engineers are necessary to address any potential conflicts and ensure the efficient operation of the system.

Space limitations

Limited space can pose challenges when installing fire-resistant ductwork, particularly in retrofit projects or buildings with complex layouts. Fire-rated ducts and fire dampers may require additional space compared to standard ductwork materials. Engaging with experienced ductwork contractors who specialize in fire-resistant installations can help find innovative solutions to overcome space limitations without compromising fire safety requirements.

Contractor expertise

Proper installation of fire-resistant ductwork requires specialized knowledge and expertise. Not all contractors may be familiar with the specific requirements and techniques associated with fire-resistant materials. It is important to collaborate with reputable contractors who have experience in fire-resistant installations to ensure the proper selection, installation, and maintenance of ductwork materials. Seeking references and verifying contractor qualifications can help ensure the success of your fire-resistant ductwork project.

This image is property of mepacademy.com.

Case studies of successful fire-resistant ductwork installations

Office building retrofit project

In a recent office building retrofit project, fire-resistant ductwork installations were instrumental in enhancing fire safety. The building, originally constructed in the 1980s, required significant upgrades to comply with current building codes. Fire-rated ducts and fire dampers were installed throughout the ventilation system to prevent the spread of fire and smoke. The successful completion of the project not only ensured the safety of the building occupants but also met the rigorous requirements of the local fire department.

Residential high-rise construction

A residential high-rise construction project incorporated fire-resistant materials in the ductwork installations to provide an extra layer of fire protection. The use of fire-rated ducts and fire-resistant coatings effectively minimized the potential for fire to spread between floors and apartments. By meeting the fire safety standards outlined by local building codes, the developer was able to provide residents with peace of mind and ensure a safe living environment.

Industrial plant expansion

During the expansion of an industrial plant, fire-resistant ductwork played a critical role in safeguarding the facility and workers. The plant, which dealt with flammable materials and processes, required robust fire protection measures. Fire-rated ducts and fire dampers were installed to create compartmentalization and limit the spread of fire in case of an incident. These fire-resistant installations proved invaluable in protecting critical equipment and minimizing the impact of potential fires on the overall operation of the plant.

Conclusion

Incorporating fire-resistant materials in ductwork installations is crucial for complying with building code requirements, enhancing safety, and preventing the spread of fire. Commercial, residential, and industrial buildings all benefit from the use of fire-resistant materials to minimize fire hazards and protect occupants and property. Fire-rated ducts, fire dampers, and fire-resistant coatings are effective solutions that provide the necessary fire resistance. By adhering to applicable building codes and regulations, ensuring proper installation and maintenance, and working with experienced contractors, you can successfully implement fire-resistant ductwork installations. Despite potential upfront costs, the long-term savings, insurance benefits, and peace of mind that come with fire-resistant materials make them an essential investment in the overall fire safety of a building.

This image is property of basc.pnnl.gov.