Did you know that ducts in your HVAC system may contain dampers? These dampers play a vital role in controlling airflow and balancing temperature distribution throughout your home. By adjusting the position of these dampers, you can ensure that each room receives the desired level of heating or cooling. This article will explore the importance of dampers in ducts and how they contribute to a more comfortable and energy-efficient indoor environment. So, let’s dive in and discover the secret behind these hidden heroes of your HVAC system!

1. Introduction

Ducts play a crucial role in HVAC (Heating, Ventilation, and Air Conditioning) systems. These systems are responsible for maintaining a comfortable indoor environment by regulating temperature, airflow, and humidity. Dampers, which are often installed in ducts, play an important role in controlling airflow and ensuring temperature distribution. In this article, we will explore the role of ducts in HVAC systems, the function of dampers, different types of dampers, the need for airflow control, components of duct dampers, guidelines for damper placement, factors to consider for damper sizing and installation, the importance of regular maintenance and inspection, and conclude with a summary of the key points discussed.

2. The role of ducts in HVAC systems

2.1 Function of ducts

Ducts are pathways that allow the circulation of air throughout a building. They serve as conduits for heated or cooled air to reach various rooms and spaces. Ducts ensure that air, which is processed by HVAC equipment, is efficiently distributed to provide optimal comfort. Without a well-designed duct system, the conditioned air might not reach its intended destinations, resulting in an imbalance in temperature distribution and reduced efficiency.

2.2 Importance of airflow control

Airflow control is essential for maintaining a comfortable indoor environment. By regulating the amount of air flowing through the ducts, dampers help balance temperature distribution and prevent certain areas from becoming too hot or too cold. Additionally, airflow control allows for energy efficiency by adjusting the airflow based on the specific needs of each zone or room. This not only enhances comfort but also reduces energy consumption and utility costs.

2.3 Temperature distribution in ducts

Temperature distribution within the ducts is an important factor to consider for optimal HVAC system performance. Ducts are responsible for conveying conditioned air, and any variation in temperature across the ductwork can affect the overall thermal comfort in different areas of the building. By using dampers strategically, temperature imbalances can be addressed, ensuring that conditioned air is evenly distributed throughout the space, regardless of the duct length or layout.

3. Understanding air dampers

3.1 Definition and purpose

Air dampers are devices installed within ducts to regulate or control the flow of air. They can be manually or automatically operated, depending on the specific requirements of the HVAC system. The purpose of dampers is to modulate airflow, adjust ventilation rates, and redirect air to different sections of the building as desired. By controlling airflow, dampers enable HVAC systems to provide optimum comfort and energy efficiency.

3.2 Types of air dampers

There are various types of air dampers available, each designed for specific functions. Some common types include volume control dampers (VCD), fire dampers, smoke dampers, pressure relief dampers, backdraft dampers, balancing dampers, and zone dampers. Depending on the system and building requirements, the appropriate types of dampers are selected to achieve the desired control and regulation of airflow.

3.3 How air dampers work

Air dampers operate by either manually adjusting the airflow using hand-operated levers or automatically through the use of actuators and controls. Manual dampers are adjusted by simply turning a handle or lever, while automatic dampers are controlled by an actuator that receives signals from a control system. These actuators can be programmed to open or close dampers based on temperature, occupancy, or other predetermined conditions. The operation of air dampers ensures that airflow is regulated and directed in a manner that promotes efficient HVAC performance.

4. The need for airflow control in ducts

4.1 Efficient HVAC operation

Efficient HVAC operation relies on the control and regulation of airflow. By using dampers effectively, an HVAC system can distribute the required amount of conditioned air to each zone or room. This allows the system to match the cooling or heating load demands, preventing unnecessary energy consumption and optimizing overall efficiency. Proper airflow control ensures that the HVAC system operates at its peak performance, providing consistent comfort while minimizing energy wastage.

4.2 Balancing temperature distribution

Temperature distribution is a critical factor in maintaining a comfortable indoor environment. Uneven temperature distribution can lead to hot and cold spots, leaving occupants dissatisfied. Dampers play a vital role in balancing temperature distribution by controlling the flow of conditioned air. By adjusting the airflow to different areas, dampers can ensure that each zone or room receives an adequate amount of conditioned air, resulting in even temperature distribution throughout the entire building.

4.3 Minimizing energy consumption

Energy consumption can be significantly reduced by implementing airflow control through dampers. By adjusting the airflow to specific areas based on occupancy and demand, HVAC systems can avoid excessive heating or cooling in unoccupied spaces. This not only conserves energy but also lowers utility costs. Effective damper control prevents over-conditioning and ensures that air circulation is optimized for maximum efficiency.

4.4 Zoning and individual comfort

Zoning is the practice of dividing a building into different areas or zones, each with its independent temperature control. Dampers are essential for achieving effective zoning, allowing occupants to customize the temperature in different rooms or areas according to their preferences. By controlling the airflow to different zones, dampers ensure individual comfort while providing efficient heating or cooling only where needed.

5. Components of duct dampers

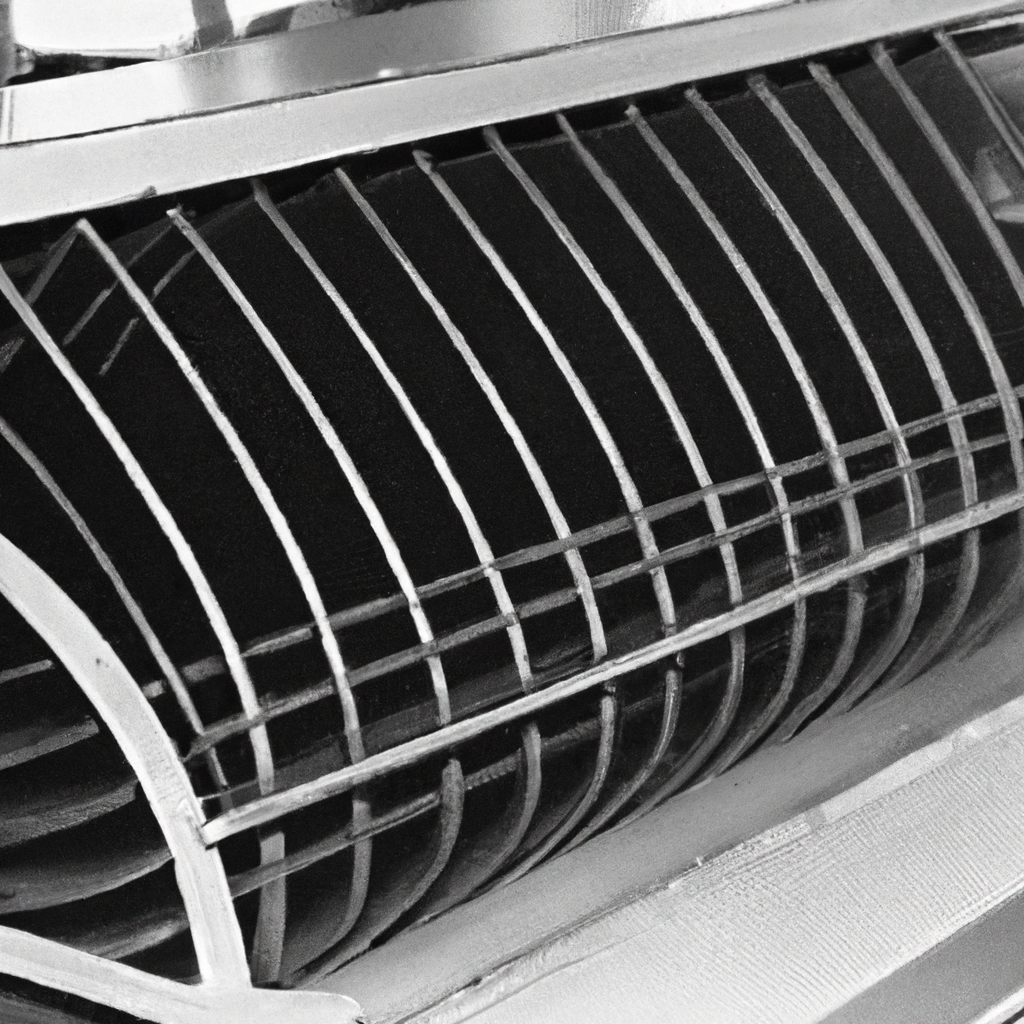

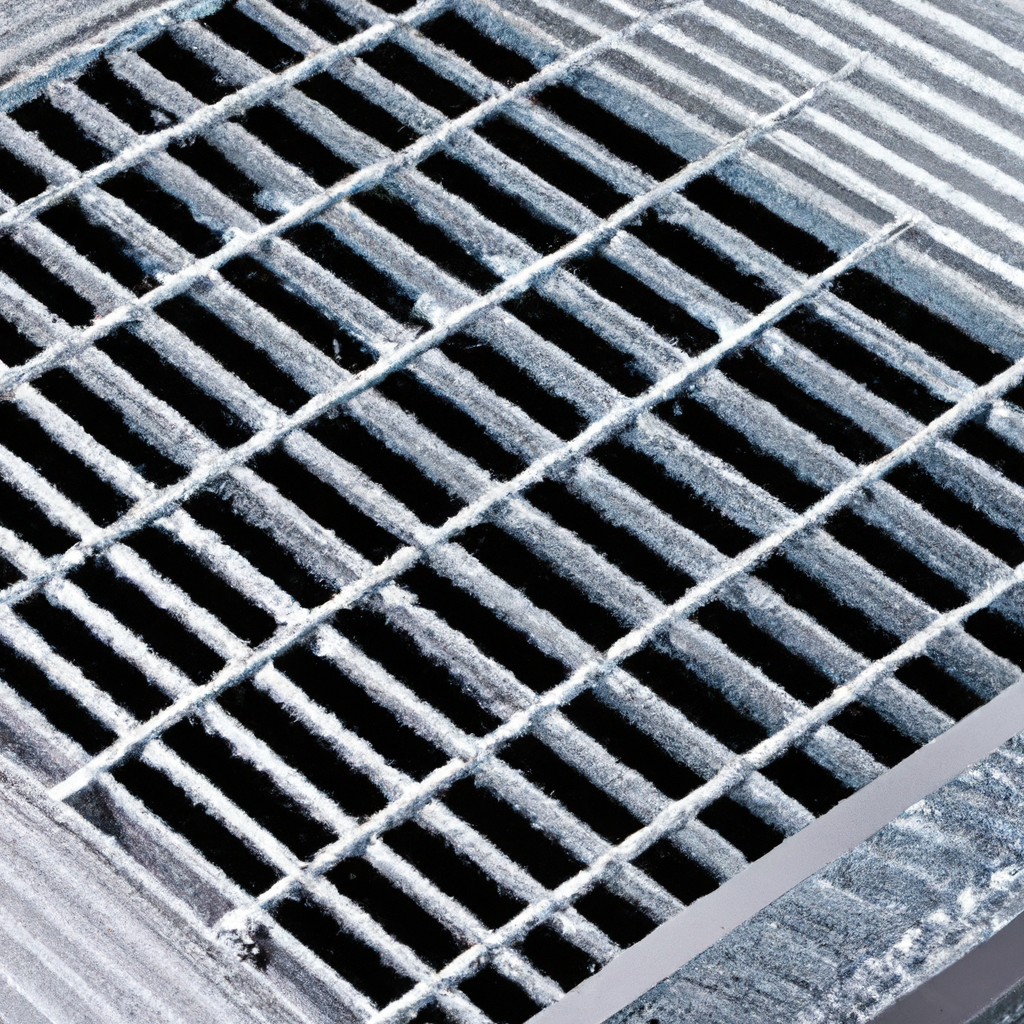

5.1 Frame and blades

Duct dampers consist of a frame and blades that regulate the airflow. The frame provides structural support and is usually made of durable materials such as galvanized steel or aluminum. The blades, often referred to as louvers, are responsible for controlling the airflow by opening or closing in response to manual or automatic control signals. The design and construction of the frame and blades play a crucial role in the overall effectiveness and longevity of the damper.

5.2 Actuators and controls

For automatic damper operation, actuators and controls are essential components. Actuators are devices that receive signals from the control system and move the blades accordingly. They can be pneumatic, electric, or motorized, depending on the specific HVAC system requirements. Controls, on the other hand, are responsible for transmitting signals to the actuators, instructing them to open or close the dampers. The combination of actuators and controls enables the precise regulation of airflow based on various environmental and system conditions.

5.3 Sealing mechanisms

Sealing mechanisms ensure proper closure and airtightness when dampers are closed. This is essential to prevent any unwanted leakage of conditioned air, which can impact the overall efficiency of the HVAC system. Seals are typically made of weather-resistant materials such as neoprene or silicone rubber. Properly installed sealing mechanisms maintain the integrity of the duct system and enhance its performance by minimizing air leakage.

5.4 Insulation and noise control

To minimize heat loss or gain and reduce noise transmission, some duct dampers are equipped with insulation. Insulated dampers help maintain the desired temperature of the conditioned air as it passes through the ducts, minimizing energy wastage. Additionally, insulation reduces noise transmission, making the HVAC system quieter and more comfortable for occupants. By incorporating insulation and noise control features, duct dampers enhance both the energy efficiency and the overall indoor environment quality.

6. Types of dampers for airflow control

6.1 Volume control dampers (VCD)

Volume control dampers, also known as VCDs, are the most commonly used dampers in HVAC systems. They are designed to modulate and regulate the volume of airflow. VCDs are typically located near the supply or return air vents, allowing for manual or automatic adjustment of the airflow rate. These dampers are essential for maintaining proper ventilation and achieving individual comfort control within different areas of a building.

6.2 Fire dampers

Fire dampers are critical safety components in ductwork systems. They are designed to prevent the spread of fire and smoke through ducts in the event of a fire. Fire dampers have a fusible link that automatically closes the damper blades when exposed to high temperatures, effectively sealing off the duct. This prevents the spread of flames and smoke to other areas of the building, providing valuable time for evacuation and limiting fire damage.

6.3 Smoke dampers

Similar to fire dampers, smoke dampers are designed to prevent smoke from spreading through a building’s ductwork during a fire. Smoke dampers are essential in smoke control systems, helping to contain smoke and toxic gases, allowing occupants to evacuate safely. These dampers have both manual and automatic operation modes and are often integrated with fire alarm systems to ensure immediate closure in case of fire detection.

6.4 Pressure relief dampers

Pressure relief dampers are used to regulate pressure differentials within the HVAC system. They are particularly important in systems where the pressure can fluctuate, such as when multiple fans operate simultaneously. Pressure relief dampers prevent excessive pressure buildup, which can lead to system inefficiency, noise, and potential damage to equipment. By releasing excess pressure, these dampers ensure stable airflow and overall system performance.

6.5 Backdraft dampers

Backdraft dampers prevent reverse airflow within the ducts. They are typically installed in exhaust systems, preventing outside air from entering through the exhaust vent when the exhaust fan is not in operation. This not only improves the energy efficiency of the system but also prevents backdrafts, which can bring in unwanted odors or contaminants from the outside. Backdraft dampers ensure that airflow is one-directional, enhancing system performance and maintaining indoor air quality.

6.6 Balancing dampers

Balancing dampers are used to adjust airflow and balance the distribution of conditioned air within a duct system. They are commonly employed in HVAC systems with multiple zones or rooms with different cooling or heating requirements. Balancing dampers are strategically placed to regulate airflow to specific areas, allowing for precise control of temperature and ensuring that each zone receives its required amount of conditioned air.

6.7 Zone dampers

Zone dampers are essential for creating independent temperature control in different zones or rooms of a building. They are typically motorized dampers that open or close based on signals from the HVAC control system. By installing zone dampers, the airflow to different zones can be adjusted, allowing for individualized temperature control and increased energy efficiency. Zone dampers enable occupants to tailor the heating or cooling in specific areas, enhancing comfort and reducing energy wastage.

7. Guidelines for damper placement in ducts

7.1 Near the main duct connections

Dampers should be placed near the main duct connections to ensure effective airflow control. By situating dampers close to the main ducts, it becomes easier to control the overall airflow entering and exiting the duct system. This placement allows for optimized airflow regulation and ensures that conditioned air is distributed efficiently throughout the building.

7.2 At branch points and takeoffs

Branch points and takeoffs are areas where the duct system branches out to supply air to different zones or rooms. Placing dampers at these points enables independent control of airflow to specific areas. By adjusting the damper position at each branch point or takeoff, the airflow to each zone can be modulated, allowing for customized temperature control and efficient distribution of conditioned air.

7.3 Near equipment and air handlers

Dampers should be positioned near HVAC equipment and air handlers to enhance system performance. By placing dampers near equipment, it becomes easier to balance the airflow and ensure that the required amount of conditioned air reaches the system components efficiently. Proper placement of dampers in these areas also facilitates maintenance and inspection, allowing for any necessary adjustments or repairs to be carried out without impacting the overall system operation.

7.4 Consideration for zoning

When implementing zoning in HVAC systems, damper placement becomes crucial. Dampers should be strategically located to enable effective management of airflow to each zone. By placing dampers near the entrances of each zone, the flow of conditioned air can be controlled, ensuring that each zone receives the desired amount of heating or cooling. Properly placed dampers facilitate precise temperature control in each zone, enhancing overall comfort and energy efficiency.

7.5 Accessibility for maintenance

It is essential to consider the accessibility of dampers for maintenance purposes. Dampers should be positioned in areas that allow for easy access, ensuring that routine maintenance tasks, such as cleaning and lubrication, can be performed without difficulty. Accessible dampers also enable inspection and troubleshooting if any issues arise. Proper planning and placement of dampers contribute to the efficiency and longevity of the HVAC system, minimizing downtime and maintenance costs.

8. Factors to consider for damper sizing and installation

8.1 Duct size and airflow velocity

When sizing dampers, it is crucial to consider the duct size and airflow velocity. The dimensions of the ductwork and the rate at which air flows through it determine the appropriate damper size. Oversized dampers may result in air leakage and increased energy consumption, while undersized dampers can cause pressure buildup and reduced system performance. Properly sized dampers ensure effective airflow control and contribute to the overall efficiency and reliability of the HVAC system.

8.2 HVAC system capacity

The capacity of the HVAC system should be considered when determining damper sizing and installation. The system’s cooling or heating capacity dictates the amount of air that needs to be distributed. Dampers should be selected and installed accordingly to match the system’s capacity, allowing for precise control of airflow to achieve the desired comfort level in each zone or room.

8.3 Noise and vibration control

Dampers can contribute to noise and vibration within the duct system. To minimize noise transmission, it is important to consider the acoustic properties of the dampers. The selection and installation of properly designed dampers with noise-reducing features can help ensure a quieter HVAC system. Additionally, dampers should be properly secured and insulated to prevent vibration and the associated noise.

8.4 Air pressure differentials

Air pressure differentials can impact damper performance and the overall airflow control within the HVAC system. Proper consideration of pressure differentials between various sections of the ductwork is necessary to ensure that dampers can effectively regulate airflow. Oversized or improperly placed dampers may result in pressure imbalances, leading to reduced airflow control and compromised system operation. Balancing pressure differentials through proper damper selection and placement is crucial for optimal system performance.

8.5 Fire and smoke safety regulations

Compliance with fire and smoke safety regulations is essential when selecting and installing dampers. Fire dampers and smoke dampers should be chosen based on the specific fire safety requirements outlined by local building codes. The proper installation of these dampers ensures that, in the event of a fire, the spread of flames and smoke through the ductwork is effectively contained, providing valuable time for evacuation and minimizing the impact of fire on the building.

9. Importance of regular maintenance and inspection

9.1 Cleaning and lubrication

Regular maintenance and inspection of dampers are crucial for ensuring optimal performance. Dampers should be regularly cleaned to remove dust, debris, and any other contaminants that may hinder their operation. Additionally, lubrication of moving parts, such as hinges and linkages, helps to maintain smooth damper operation and prevents excessive wear and tear.

9.2 Damper operation testing

Periodic testing of damper operation is necessary to identify any issues or malfunctions promptly. Testing should involve opening and closing the dampers manually or through the control system to ensure they operate smoothly and as intended. Any signs of resistance or irregular movement should be addressed promptly to maintain the effectiveness and reliability of the dampers.

9.3 Sealing and insulation integrity

Sealing and insulation integrity should be inspected regularly to prevent air leakage and temperature loss or gain. Damaged or deteriorated seals should be replaced, and insulation should be checked for any signs of degradation. Maintaining the integrity of the sealing and insulation ensures optimal damper performance and minimizes energy wastage.

9.4 Troubleshooting common issues

Regular maintenance and inspection provide an opportunity to troubleshoot common damper issues. Any issues, such as improper damper operation, unusual noises, or airflow imbalances, should be investigated and resolved promptly. Identifying and addressing these issues at an early stage helps maintain the performance and efficiency of the HVAC system, preventing potential problems from escalating into major repairs or replacements.

10. Conclusion

Ducts with dampers play a vital role in HVAC systems by controlling airflow and balancing temperature distribution. Understanding the function and importance of dampers allows for the effective design, installation, and maintenance of duct systems. By implementing proper airflow control, HVAC systems can operate more efficiently, provide uniform temperature distribution, minimize energy consumption, and enhance individual comfort. The selection and placement of appropriate dampers, along with regular maintenance and inspection, contribute to the overall performance and longevity of HVAC systems. By following the guidelines outlined in this article, you can ensure that your ducts and dampers work together seamlessly, providing optimal comfort and energy efficiency in your building.